November 13, 2014

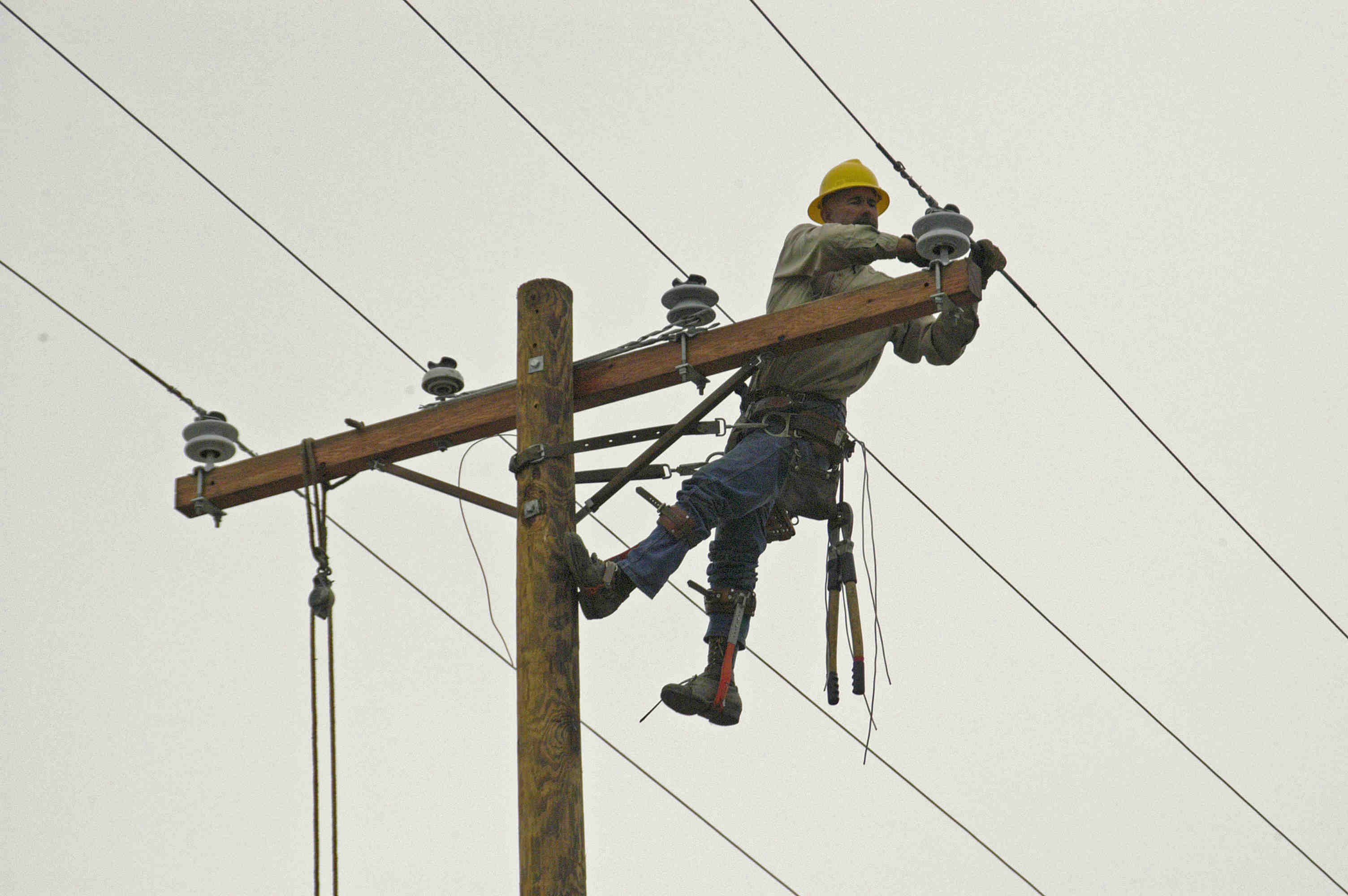

Power Line Installer Safety Training

November 13, 2014

More than any other discovery or invention, electricity has transformed the way that people live their lives. It’s nearly impossible to imagine going without it for a few hours, much less a day. Below, you’ll find a list of training topics that are required for most Power line installers.

Fall Protection OSHA Regulation: 1926.503(a)

Required for each employee that may be exposed to fall hazards. See full OSHA regulation for more details.

When there is a change in the workplace or the employer has reason to believe that a trained employee does not have the understanding and skill necessary to perform the job safely.

Electrical OSHA Regulation: 1910.332

When an employee faces the risk of electric shock that is not reduced to a safe level by engineering controls. See full OSHA regulation for more details.

None specified.

Ladder / Stairway OSHA Regulation: 1926.1060

Employees that are required to use ladders or stairways should be trained on the hazards associated with their usage. See full OSHA regulation for more details.

Provide retraining so that the employee maintains the understanding and knowledge acquired from the training.

First Aid OSHA Regulation: 1910.266 App B

In the absence of a nearby hospital or clinic (more than 4 minutes away), a designated employee should be trained to render first aid. See full OSHA regulation for more details.

Retraining for life threatening emergencies should occur annually. Retraining for non-life-threatening response should occur ‘periodically’.

Lockout Tagout OSHA Regulation: 1910.147(c)(7)

When an employee works in area that contains machinery that is locked out / tagged out. See full OSHA regulation for more details.

When there is a change.

Manlifts OSHA Regulation: 1910.66(i)(1)

When an employee is required to operate a working platform as part of their job. See full OSHA regulation for more details.

None specified.

Personal Protective and Respiratory Equipment OSHA Regulation: 1910.132(f)

When an employee is required to wear PPE, they must be trained on its usage. See full OSHA regulation for more details.

Retraining required when the type of PPE changes, employee demonstrates inability to use PPE properly, or when the workplace changes in a way that renders previous training obsolete.

Eye Safety

Annually

Heat Stress

Annually

Slips, Trips and Falls

Annually