March 12, 2025

The 5 Deadliest Arc Flash Safety Mistakes (And How to Fix Them)

March 12, 2025

Electricity is a beast. It is the lifeblood of modern industry, but it is also one of the most unforgiving forces on the planet. If you disrespect it, even for a microsecond, it will remind you why you shouldn’t. And of all the hazards electricity presents, none is more violent, more destructive, or more terrifying than an arc flash.

An arc flash isn’t just a “spark.” It is a catastrophic release of energy that can reach temperatures of 35,000°F, four times hotter than the surface of the sun, in a fraction of a second. It vaporizes metal, sends shrapnel flying at 700 miles per hour, and creates pressure waves strong enough to collapse a lung.

Yet, despite these stakes, arc flash safety mistakes happen every day. They happen because of complacency, rushing, or a fundamental misunderstanding of the risk. This guide breaks down the five deadliest errors workers make and provides the roadmap to ensure your team goes home safe.

Before we fix the mistakes, we have to understand the enemy. An arc flash occurs when an electric current leaves its intended path and travels through the air from one conductor to another, or to the ground. This creates a short circuit, but unlike a typical short, the air itself becomes ionized and conductive.

The result is an explosion of heat, light, and sound. The immediate dangers include:

The number one cause of industrial accidents isn’t equipment failure; it’s human error driven by complacency. We’ve all heard the excuses:

The Fix: Treat every task as if it’s your first time doing it. In arc flash safety, “routine” is a dirty word. Enforce a culture where following protocol is praised over speed. If a worker is caught taking a shortcut, it needs to be addressed immediately, not as a punishment, but as a life-saving intervention.

Too many companies jump straight to PPE (Personal Protective Equipment) as their primary defense. “Just throw on the arc flash suit and you’re good.” This is a deadly mistake. PPE is the last line of defense, not the first.

The Fix: Follow the Hierarchy

You cannot protect yourself from a hazard you haven’t measured. Guessing the incident energy level is like playing Russian Roulette. Without a proper Arc Flash Risk Assessment (as required by NFPA 70E), you have no idea what level of protection you need.

The Fix: Know Your Boundaries A proper assessment defines these critical zones:

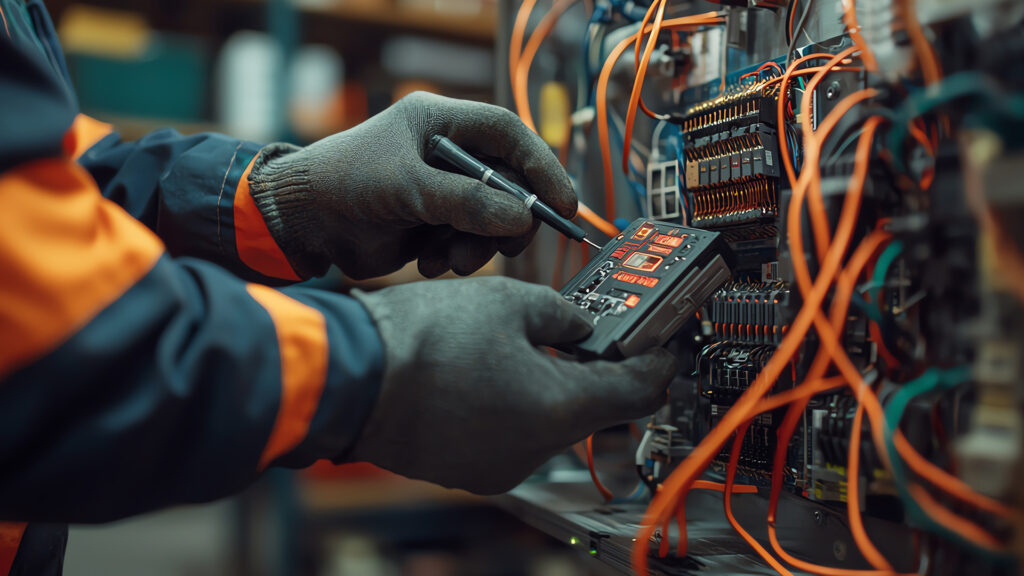

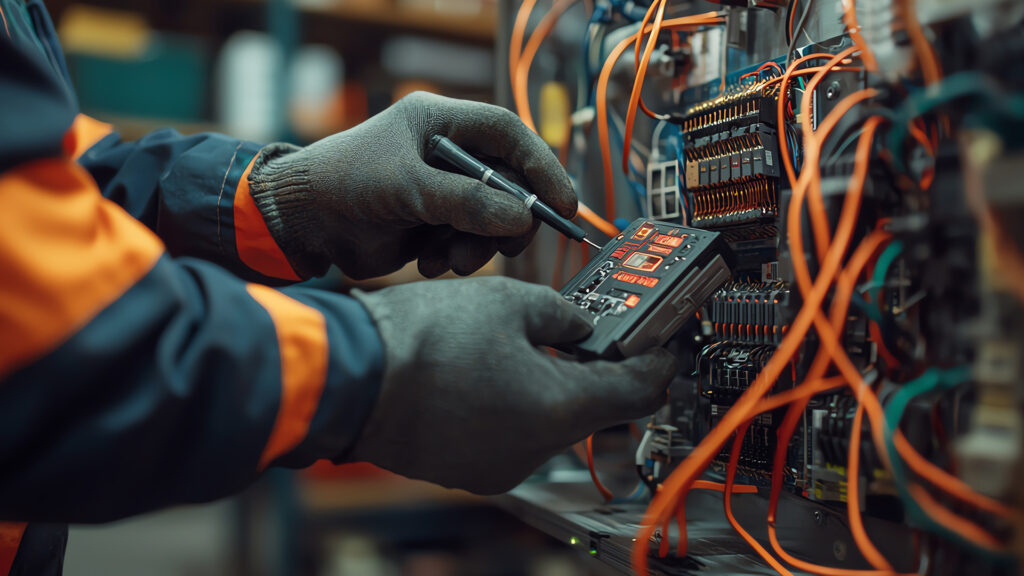

Turning off a breaker isn’t enough. Breakers fail. Circuits can be back-fed. The mistake here is assuming the power is off without proving it.

The Fix: Test Before You Touch Always follow the “Live-Dead-Live” test:

Only then can you apply your LOTO locks and tags.

Wearing a suit that is rated for 8 cal/cm² when the blast potential is 40 cal/cm² is like using an umbrella in a hurricane. Furthermore, wearing the right suit incorrectly (like rolling up sleeves or wearing synthetic underwear) can lead to catastrophic injuries.

The Fix: Care for Your Gear

The human cost of an arc flash is incalculable, lives lost, families destroyed, and careers ended. But the business cost is also staggering. OSHA fines for electrical violations can reach hundreds of thousands of dollars. Medical costs, litigation, and equipment replacement can run into the millions. It is simply cheaper to be safe.

You can buy the best gear in the world, but if your team doesn’t know how to use it, you’re still at risk. Training is the glue that holds your safety program together.

Our Electrical Safety: Arc Flash Prevention Training Course is designed to move beyond the basics. We dive deep into NFPA 70E compliance, hazard analysis, and the practical realities of working safely around energized equipment.

Don’t wait for an accident to audit your safety program. Identify these mistakes today, fix them tomorrow, and keep your lights on and your people safe.

The most common cause is human error, such as dropping tools on live bus bars, failing to properly verify that equipment is de-energized, or using the wrong test equipment.

Electric shock happens when current passes through the body. Arc flash is an external explosion of energy around the body. While they often happen together, arc flash causes burns and blast injuries without the worker necessarily touching the live part.

According to NFPA 70E, retraining is required at least every three years. However, additional training is needed if an employee is found to be non-compliant, if new equipment is introduced, or if job duties change.