August 17, 2018

Forklift Safety Training Debunked

August 17, 2018

This general forklift safety overview will cover the basic standards and OSHA requirements for driving an industrial truck. Forklifts or lift trucks are common machines used in industrial, construction and various other workplace settings. These types of powered industrial trucks are used to raise, lower, move, and relocate materials on the job site. OSHA requires employees that are going to be using these trucks are trained on how to use them safely and correctly.

The standard for Powered Industrial Trucks, Subpart N, including 29 CFR 1910.178 goes over the different kinds of powered industrial trucks (motorized hand trucks, fork trucks, tractors, platform lift trucks, and other trucks that are essentially powered by internal combustion engines or electric motors), how to operate them and use them, how to inspect them, fire protection, and maintenance procedures. It’s crucial your forklift employees are fully trained and certified before operating these machines.

There’s a ton of issues that can arise if an employee is not properly trained. Injuries to your workers, injuries to the individual using the forklift, damages to your facility, and other operating hazards can be prevented if safety training is made available. Powered industrial trucks can weigh anywhere from 9,000 lbs. to an upwards of 30,000 lbs. (depending on what type and job function) and can travel roughly 20 mph, making them dangerous heavy machines.

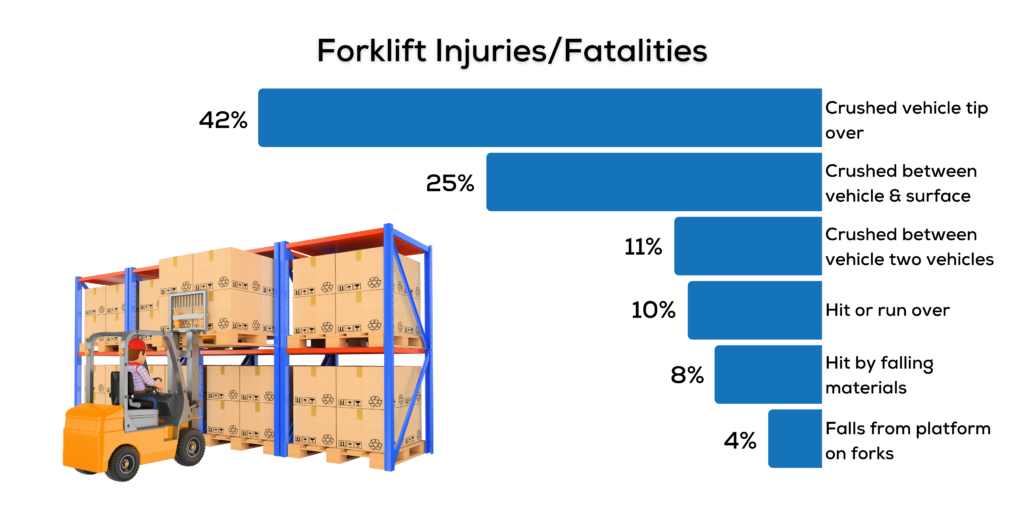

OSHA estimates that forklifts cause about 85 fatal accidents per year. Around 34,900 serious accidental injuries and 61,800 non-serious injuries. The most common types of accidents happen when other employees in the area are struck, pinned, or hit by a forklift, the forklift tips over or overturns, and workers falling from their forklift. With the proper training, almost all accidents can be avoided. According to OSHA, 70% of forklift accidents could have been avoided with standardized training. Below is a graph of the most common forklift injuries/fatalities types for operators.

A competent instructor or trainer is the one who should be conducting the forklift training in the classroom and on the job site. A competent person according to OSHA is defined as an individual who is capable of identifying the hazards in and around the workplace, is knowledgeable of the current standards, knows the hazards and risks associated with specific operations, and has the authority to correct any issues.

Training for powered industrial trucks includes classroom and hands-on training. Classroom training will consist of either a video, PowerPoint training, or even online training courses. Those will go over the general OSHA rules and standards for powered industrial trucks. Most classroom training will include:

Employees will be tested on their knowledge before getting their practical training on the forklift itself. A comprehensive evaluation of the operator’s performance on the forklift will be conducted once hands-on training has started. Before operating the forklift, your employees should complete a formal documented pre-use inspection form. Pre-trip inspections will require your operators to overlook the physical conditions of the forklift. They can expect to:

After the pre-trip inspection, your employees will then do a pre-operation inspection. The difference with the pre-operation inspection is that the engine will be running. After inspections are complete and everything has been deemed safe, your employee can enter the forklift and start operation training.

Forklift operators must be retrained every three years according to OSHA standard. This is to ensure that your operators retain their knowledge and skills. Refresher training can also be conducted but those evaluations are used in certain situations. Refresher training can occur when an operator is involved in an accident or near miss, observed to be operating in an unsafe manner, determined to need retraining by management, will be operating a different type of powered industrial truck, or workplace conditions have changed. No matter the situation, it’s important that any employee dealing with forklifts follows the standards, is fully trained and understands the risks.